Bending

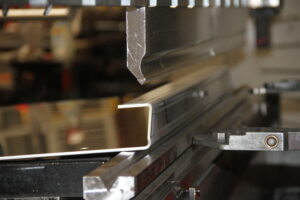

State-of-the-art technology and high-precision machines are at the heart of our range. With three ERMAK numerically controlled edging machines, we are setting new standards in efficiency and precision.

- Maximum material thickness: 15 mm

- Maximum material length: 3000 mm

- Pressing force: Up to 320 tonnes

Would you like to learn more?

Contact usAutomation and precise positioning during bending

Our edging machines are equipped with computerised controls and automatic axis stops to ensure precise positioning of the bent workpiece.

Thanks to the automatic deflection correction system, we can also bend long elements with maximum precision.

Another highlight is our well-equipped stock of punches and moulds, which enables us to handle an immense variety of tasks. Whether simple or highly complex shapes are required - we always have the right tools to hand.

Quality assurance according to ISO 9001/2015

Quality is our top priority! Our processes are strictly monitored in accordance with the ISO 9001/2015 quality management system.

Use cases and application areas

Our processes are suitable for a wide range of applications:

- Industrial sectors: From mechanical engineering to automotive and construction.

- Variety of materials: We work with a wide range of materials including steel, aluminium, sheet metal and plastics.

- Flexibility: Even thin sheets can be bent into the desired shape with high precision.

Our aim is to provide each customer with a perfectly tailored solution. Our team is always on hand to help and advise!

Perfectly bent sheet metal with BudExpert

Get free advice now and start your project online. Our comprehensive services include cutting, bending and welding - all from a single source!